Modern product development demands solutions that balance speed, quality, and cost. One method stands out for transforming how industries create plastic components. This approach merges engineering precision with streamlined workflows, making it ideal for businesses aiming to stay competitive.

This technique excels at producing durable parts for consumer goods, medical devices, and automotive systems. It accounts for nearly one-third of all plastic manufacturing by weight globally. Companies can scale production from prototypes to 10,000 units without lengthy delays or excessive costs.

The process eliminates common bottlenecks in traditional methods. Designers and engineers gain flexibility to refine products while maintaining tight deadlines. Clients receive consistent results, whether they need small batches or mid-volume orders.

Key Takeaways

- Accelerates product development cycles while maintaining quality standards

- Supports production volumes from prototypes to 10,000 units

- Accounts for 32% of global plastic manufacturing by weight

- Reduces costs compared to conventional production methods

- Enables quick design adjustments during manufacturing phases

Understanding Rapid Injection Molding

Manufacturers constantly seek methods that deliver both speed and reliability in component creation. This approach combines precision engineering with optimized workflows, creating a bridge between prototyping and full-scale manufacturing cycles.

What Is This Manufacturing Technique?

At its core, this method forces molten thermoplastic materials into custom-designed molds under intense pressure. The material cools rapidly, forming durable components ready for use in days rather than weeks. It’s particularly effective for creating functional prototypes or batches under 10,000 units.

Essential Principles for Success

Three factors drive consistent results: temperature regulation, pressure control, and cycle timing. Engineers balance these elements to maintain structural integrity while accelerating timelines. Precision mold design ensures each iteration matches exact specifications, even during mid-run adjustments.

This technique supports various thermoplastics, from ABS to polycarbonate, adapting to different industry requirements. By minimizing tooling setup periods, businesses reduce lead times by up to 70% compared to conventional approaches. The streamlined workflow allows teams to test designs and scale output without costly delays.

Differences Between Standard and Rapid Injection Molding

Manufacturing timelines often dictate which production method proves most effective. Traditional approaches prioritize large-scale output, while modern alternatives focus on agility. Understanding these distinctions helps businesses choose the right strategy for their projects.

Speed and Flexibility Advantages

Shorter lead times define modern manufacturing techniques. Reduced setup periods allow teams to move from design to finished parts in weeks instead of months. This agility supports iterative testing and last-minute adjustments without derailing schedules.

Adaptability shines in fluctuating markets. Companies can pivot designs or scale output up/down as demand shifts. This responsiveness minimizes inventory waste and keeps businesses competitive during product launches.

Tooling and Material Considerations

Simplified mold designs cut initial costs and accelerate production starts. Aluminum tools, for example, offer durability for mid-volume runs without the expense of hardened steel. This balance suits businesses needing 500–10,000 units.

Material options vary between methods. Standard processes often use specialized polymers for extreme conditions, while quicker methods handle common thermoplastics like ABS or polypropylene. Each approach serves distinct performance needs.

The Rapid Injection Molding Process

Creating functional plastic components requires precision at every step. This approach combines digital design tools with controlled manufacturing phases to deliver accurate results. Teams focus on three core stages: digital modeling, material transformation, and component finishing.

Design and Prototyping Stage

Engineers start with CAD software to build 3D models of the component. They define wall thickness, surface textures, and material compatibility early in this phase. Physical prototypes made through 3D printing allow teams to test ergonomics and functionality before tooling begins.

This stage reduces errors by identifying potential flaws in gate placements or draft angles. Adjustments to the digital model cost less than modifying production tools later. Iterative testing ensures the final design meets performance requirements while staying manufacturable.

Injection and Cooling Cycles

Thermoplastics are heated to liquid form and forced into the prepared mold cavity. Pressure settings ensure material fills intricate details without air pockets. The table below shows critical parameters for this phase:

| Phase | Key Parameters | Purpose | |

|---|---|---|---|

| Injection | Temperature: 400–500°F | Pressure: 1,500–2,500 psi | Fill mold completely |

| Cooling | Time: 15–60 seconds | Channel Design: Helical | Prevent warping |

Cooling channels within the mold structure regulate solidification speeds. Uneven cooling can cause defects like sink marks or internal stresses. Ejector pins then remove finished parts once they reach optimal hardness.

Automated systems monitor cycle times and material consistency throughout production. This ensures each batch meets specifications while maintaining faster turnaround than conventional methods.

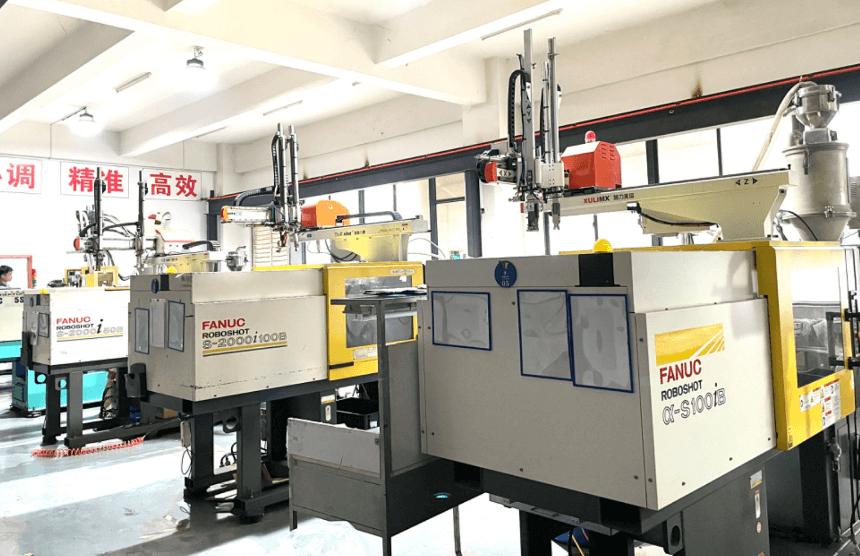

Mold Making and Equipment for Rapid Injection Molding

Precision tooling forms the backbone of efficient component production. Advanced manufacturing relies on specialized equipment to create durable molds quickly. This phase determines part quality, turnaround speed, and overall project costs.

Aluminum Molds and CNC Machining

Aluminum molds dominate short-run manufacturing due to lower costs and faster production. Unlike steel alternatives, these tools require 60% less machining time. CNC centers carve complex geometries with tolerances under ±0.005 inches.

Computer-guided cutting tools shape aluminum blocks into functional molds within days. This method supports intricate designs while maintaining structural integrity for 5,000–10,000 cycles. Multi-axis machines handle undercuts and thin walls that challenge manual operators.

EDM Techniques and 3D Printing Applications

Electrical discharge machining (EDM) creates ultra-fine details in hardened metals. Spark erosion produces sharp corners and micro-features impossible with traditional drills. This technique complements CNC work for high-precision medical or aerospace components.

3D printing accelerates prototype development by producing mold inserts overnight. Designers test gating systems and cooling channels before final tooling begins. Some printers directly create low-volume production parts using heat-resistant polymers.

Modern facilities combine these technologies to address diverse project needs. Automated quality checks ensure every mold meets specifications before entering production cycles.

Cost-Effective Production and Short Lead Times

Businesses face constant pressure to reduce expenses while accelerating product launches. This manufacturing approach addresses both challenges through optimized workflows and strategic material choices. Aluminum tooling plays a crucial role, offering durability for mid-sized runs without steel’s higher price tag.

Lower Tooling Costs and Fast Turnaround

Aluminum molds cut initial expenses by 40-60% compared to steel alternatives. These tools require fewer machining hours and handle 5,000-10,000 cycles effectively. One industry leader notes: “Our clients achieve breakeven points 30% faster using simplified tool designs.”

Three factors drive shorter lead times:

- CNC machining completes molds in 3-5 days versus weeks

- Automated quality checks reduce error correction time

- Standardized materials speed up cooling cycles

Companies testing new products benefit most. A startup can launch 500-unit batches within 2 weeks, spending 70% less than traditional methods. This flexibility lets businesses adjust designs between production runs without major cost penalties.

Budget-conscious teams gain particular advantages:

- No minimum order quantities for prototype testing

- Per-part costs stay predictable across small batches

- Scaling production requires minimal additional tooling

Versatile Applications Across Industries

From everyday gadgets to life-saving tools, advanced manufacturing methods shape countless products. Industries rely on these processes to create components that meet strict performance and safety standards. The ability to adapt materials and designs makes this approach indispensable across sectors.

Automotive, Consumer Electronics, and Medical Devices

Vehicle manufacturers use durable plastic parts like dashboard panels and connectors that withstand vibrations and temperature changes. Electronics companies produce sleek smartphone cases and responsive buttons using precise tooling. Medical teams depend on components with smooth surfaces and tight tolerances for devices like inhalers and surgical tools.

Other Key Industry Uses

Aerospace engineers select materials with high strength-to-weight ratios for cabin elements and air ducts. Consumer goods brands test toy prototypes and sports gear designs quickly before full-scale launches. Even construction firms benefit from specialized fasteners and equipment housings made through efficient production cycles.

This flexibility supports both niche markets and mass-produced items. Companies maintain quality while responding to shifting consumer needs, proving modern techniques work far beyond factory floors.

Ready to Discuss Your Injection Molding Project?

Our team of experts is ready to help you navigate the complexities of plastic injection molding for your specific application. Contact Our Injection Molding Specialists Now!